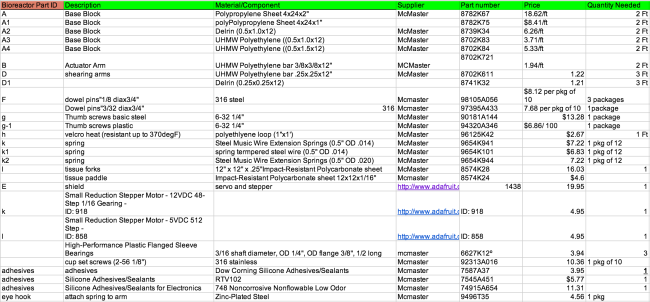

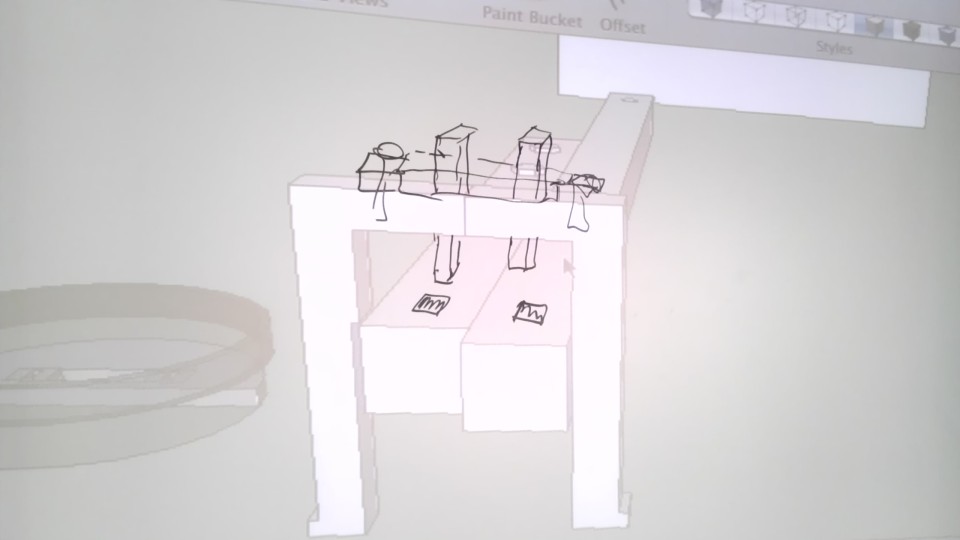

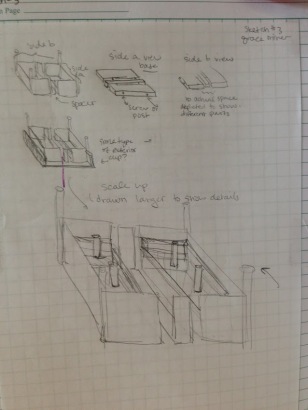

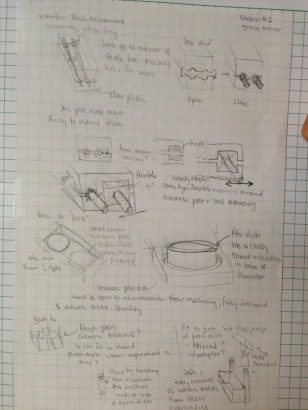

With a (somewhat) complete model sketched up, the group has a discussion on the specific parts needed. As the deadline is approaching, we needed to:

a) select which specific materials we need for each part

b) the type of material we need for each part

c) what vendors to buy from

The group decided on this parts list:

_____________________________________________________________________________

_____________________________________________________________________________

…and the order was placed!