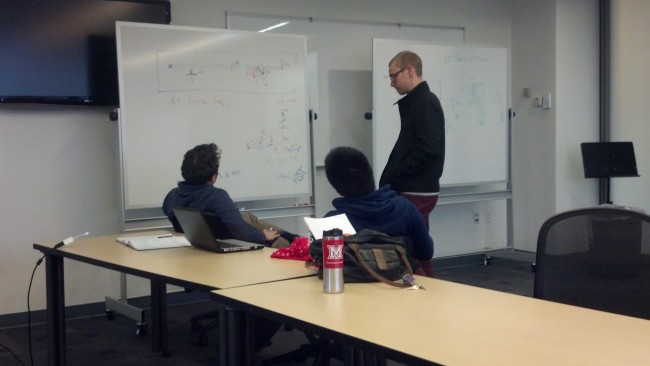

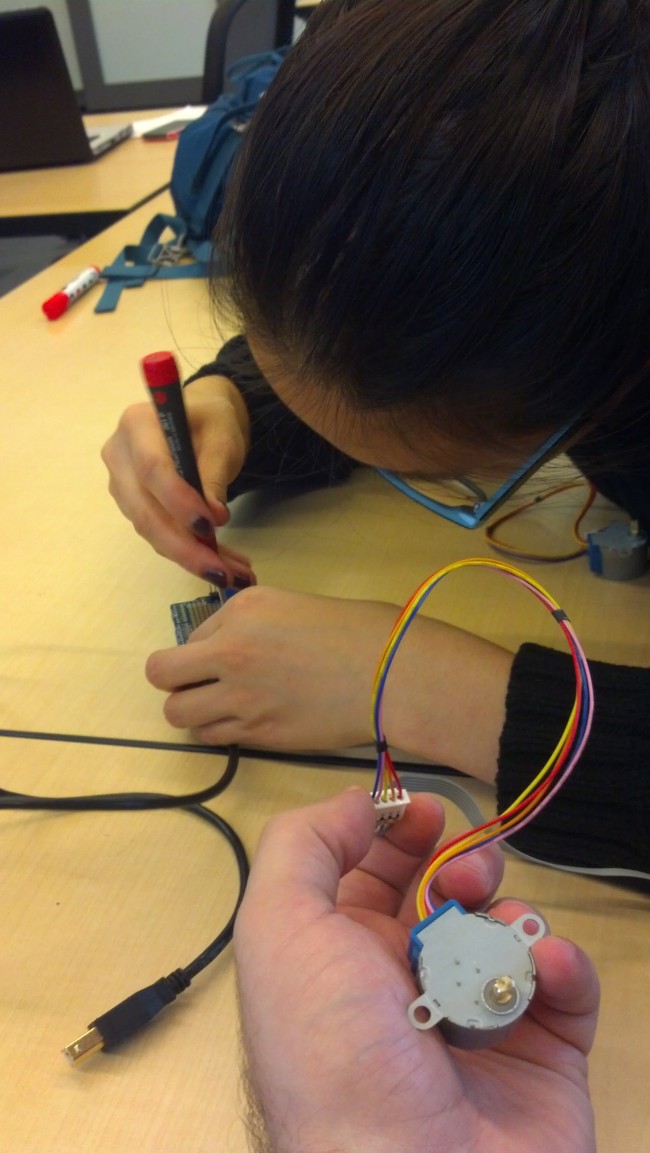

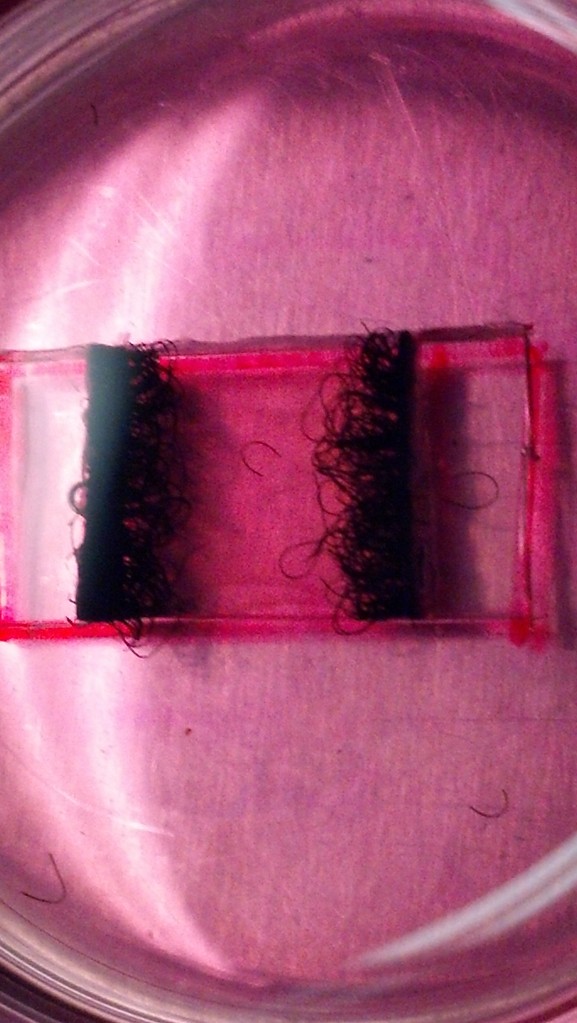

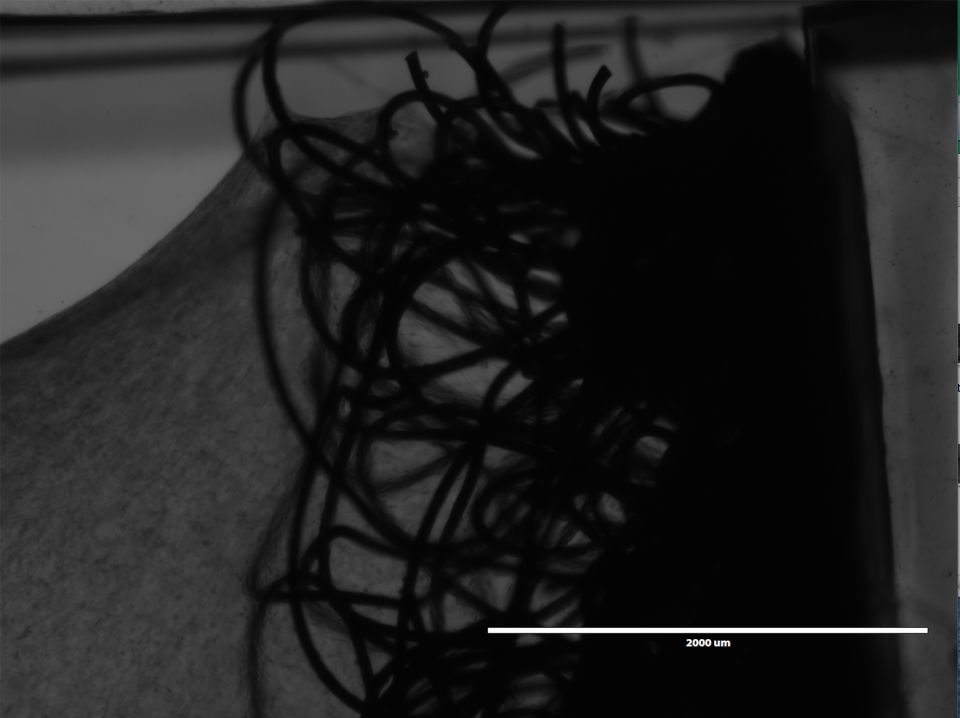

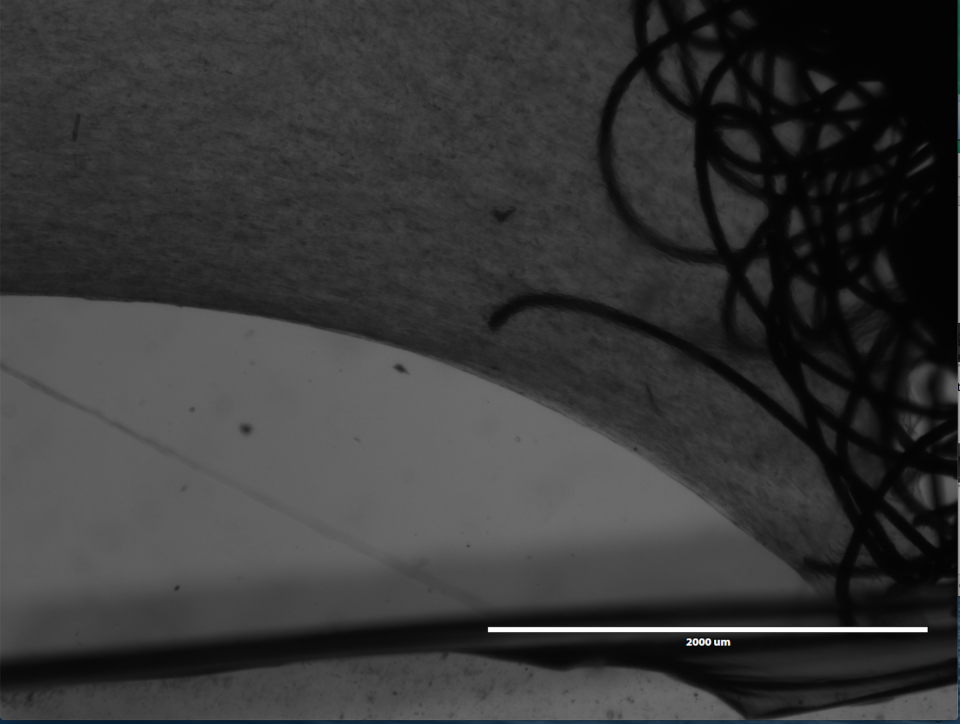

Kevin continued to work to optimize the SolidWorks file. This was an important step because many of these parts will be sent off for machining and processing (both at Mount Sinai and the Zahn Center at City College). Issues have arisen in terms of connecting the parts of the bases together as well as motor space requirements. There are some problems with motor power and the group ordered a stronger Bipolar Stepper Motor as a possible fall back, but the size of this new motor is a lot larger than the previous one.

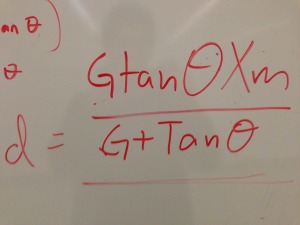

These seemingly minute issues can have large impact on the machining process so these changes are important to finalize early on as to prevent wasting of time/effort/money. Attached is an updated sketch from SolidWorks made by Kevin that demonstrates the bioreactor mechanism of action through a different angle: