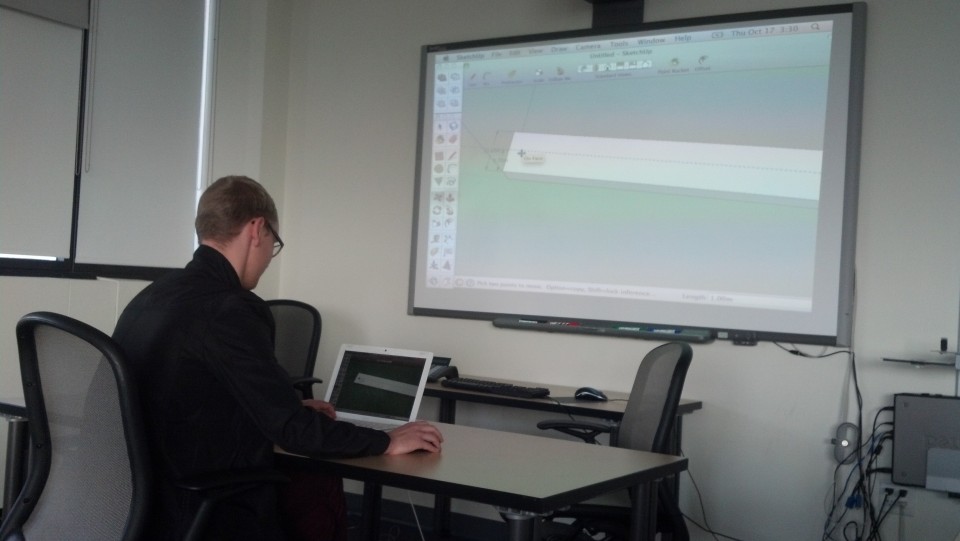

With some of the arm sizes and necessary movements, Mitch is hard at work updating the 3D model to incorporate the updated calculations.

Author Archives: pakt01

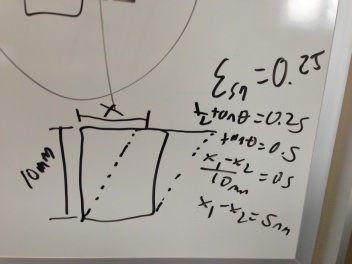

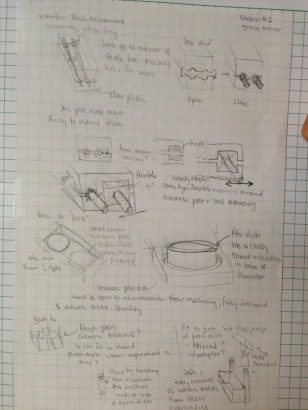

Internal design mechanics

With the candidate bioreactor modeling underway, the group needed to figure out the mathematical measurements for achieving the range of shear stress we aim to perform. This range (tentatively 0.05-0.25, with 5-6 equal increments and one control) was extrapolated to the amount of movement the machine needs to perform. These measurements will be incorporated into the model. The next steps are to update the model to fit.

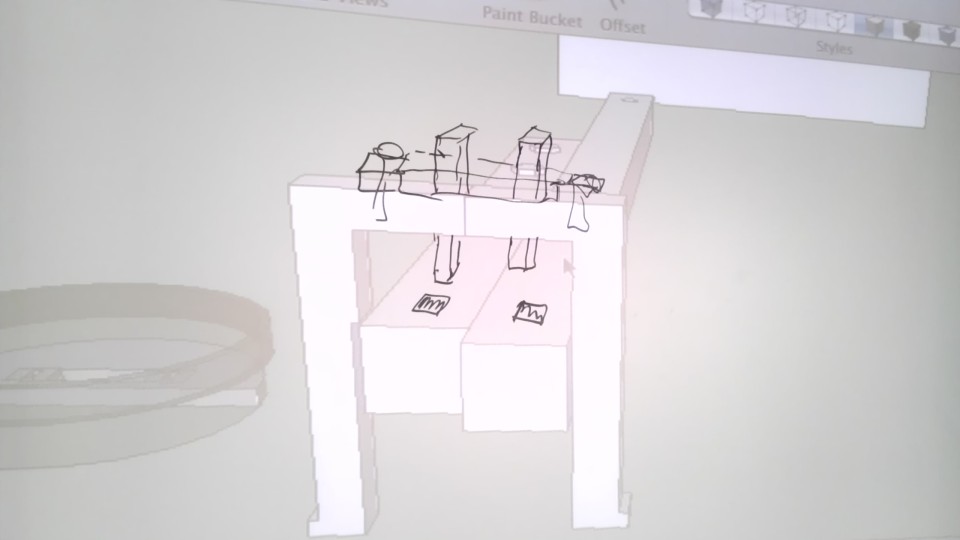

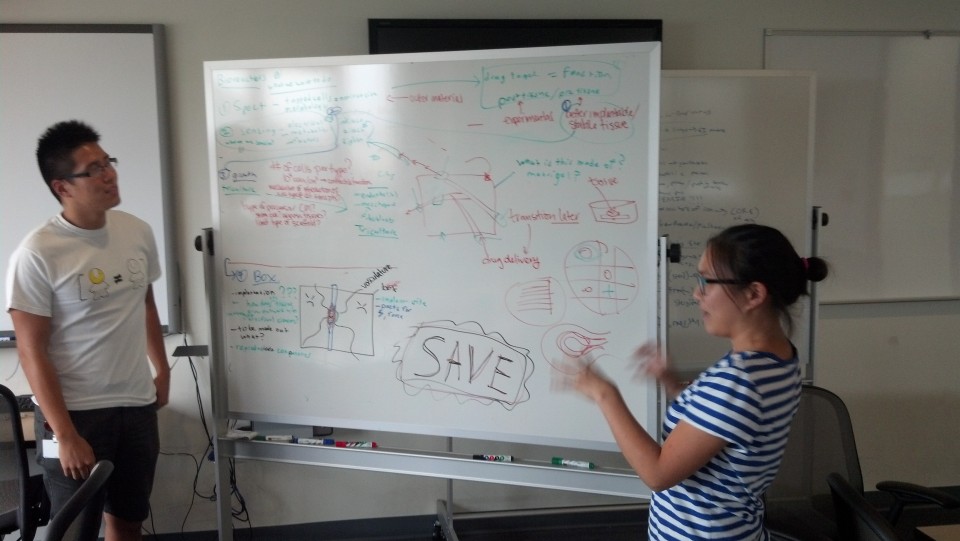

Updating 3D Model: Getting Into Specifics

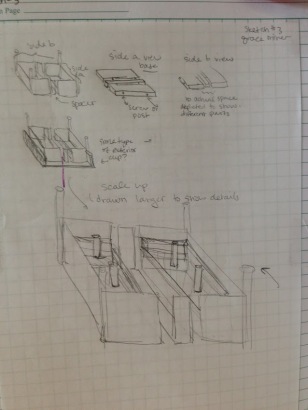

With Mitch’s initial 3D model, Pete helped the group think about the specifics of how the model will work. This process included thinking about mechanism and movement mechanics and trying to fit them within this model and current design. This exercise was completed by projecting the current model onto the SMART whiteboard and drawing additions onto it.

Initial 3D Modeling

Sketches

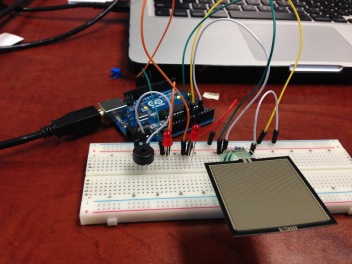

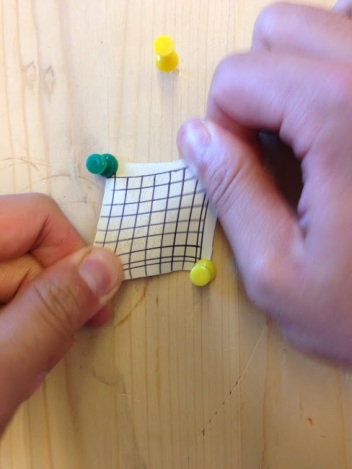

Arduino Tutoring Session

Understanding the mechanisms, specifically coding and engineering, behind Arduino.

We learned about the wonderful world of Arduino as a potential tool to facilitate our modeling process. Arduino can be interfaced with a computer and bioreactor to control output (e.g. motor) and receive input (e.g. response data). Edwin at City College taught us the basics and gave us tools to further our understanding.

Setting Up Project Management Tools

In addition to this website blog, we decided on Freedcamp as a management tool to facilitate communication as well as share to-do lists, ideas, design documents and such.