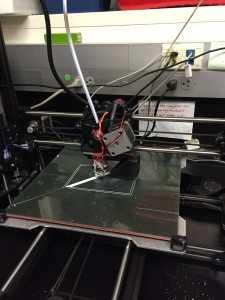

In order to 3D print our parts, Kevin has graciously allowed us to use the Lulzbot TAZ 4 3D Printer that’s in his lab. Just as a quick overview of what we’re up against: the Lulzbot TAZ offers important upgrades to traditional 3D printing that make it even more robust and capable than before, especially in the context of print quality and consistency. It’s also able to print using a variety of traditional filaments such as PLA, ABS, and HIPS as well as non-traditional filaments derived from nylon, wood, stone, and rubber precursors. Fun fact for your next trivia night: the Lulzbot 3D printers are the first hardware products to receive the Respect Your Freedom certification from the Free Software Foundation, meaning users can not only modify and adapt the various pieces of the Lulzbot to fit their needs but also use free software programs such as FreeCAD, OpenSCAD, and Slic3r to feed their CAD files into the printer.

Here’s a video from the company if you got bored of reading the above and are just about ready to move on to the next paragraph in this blog post:

Stock photos and videos aside, here’s an actual picture of the Lulzbot in Kevin’s Lab:

With Pete, Joe, and Mike’s help, we were able to figure out how to convert our SolidWorks files into a format that is recognizable by the Lulzbot.

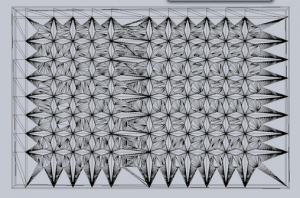

Slic3r is a tool that allows conversion of our 3D printing model into a format that the printer is able to recognize. It cuts the model into horizontal slices or “layers”, generates appropriate toolpaths to fill these layers, and calculates the amount of material that needs to be extruded to fit the right dimensions.

Here’s a picture of the “layers” that were generated by Slic3r:

Once this was done, the next step was to print! Here’s a picture of the Lulzbot lulzbot-ing:

All’s well on the field, right?

Wrong.

After the first (second, third, who’s counting really?) few times we tried printing, the printer stopped printing as soon as the base layer was extruded and set. In other words, the 96 plungers that are the most crucial aspect of this plunger piece were MIA. And we ended up with only the flat base (shown below), appropriately titled, “The Postcard.”