RECAP:

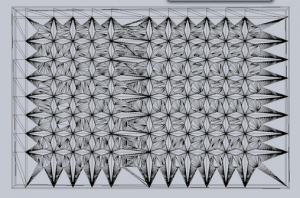

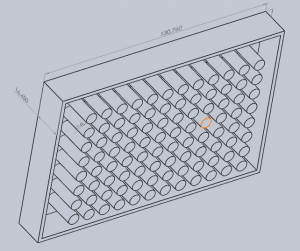

We chose to use 3D printing to manufacture the LidPlungers because the piece required precise and accurate dimensions to achieve uniform compression.

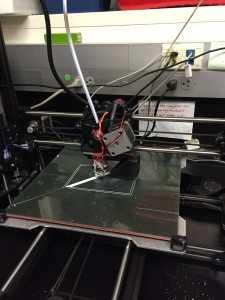

Our first attempts at printing used the Lulzbot TAZ4 with Kira (software) rendering software. The Lulzbot is a higher-end consumer 3D printer with ~75 micron resolution and can support multiple materials for printing.

UPDATE:

Our specific design turned out to be extremely challenging for the Lulzbot. On our first print attempts, the printer would lay the base structure before plastic built up at the release valve, causing the printer to fail. Conversations with the manufacturer revealed that the Lulzbot might not be able to handle repetitive, small designs (like the plungers) because it requires the plastic flow to start and stop so rapidly.

While a switch from Kira to Slice3 rendering software was able to get the printer to complete the piece, the final product was not structurally sound. Fragments of plastic were breaking off and the piece was extremely flexible.

The team switched to printing on the 3D Systems Projet 3500 HD max, recently set up in the Mount Sinai Prototyping Center. A few features made this the more attractive printer; 1) it could print with much higher resolution, 2) its proprietary plastic would harden after printing, reducing breaking and bending, 3) it simultaneously printed a supporting wax to ensure no structural deformation.

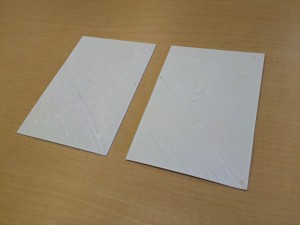

The final product seemed extremely promising. The structure seemed solid and accurate, however, we couldn’t confirm until the wax melted away.

We set one piece in the oven at 60 degrees C to melt, and two others were left at room temperature in the lab. All three pieces warped and shrank, folding the plungers inward. Furthermore, we found the structure to be quite soft when immediately removed from the oven. The warping and shrinking meant that the piece couldn’t properly fit in the well plate with free movement. With Phil Cook’s help, we were able to reduce warping by reheating and cooling, but the shrinking had taken its toll.

Phone calls with the manufacturer revealed that warping is a common occurrence with designs that have a thin, flat sheet (the base of the plungers). 3D systems recommended 1) thickening the base 2) reprint with the piece slightly rotated about the z-axis, and 3) melt the wax without rapidly heating and cooling the piece.

Thankfully, the final product supported free movement through the wells and was sufficient for a proof of concept. It should be noted, however, that the piece still warped and shrank, even with a 5mm base.

Given our experiences with 3D printing and conversations with manufacturing, it seems that this particular design is not right for printing. The materials cannot support the thin base and repetitive column design. Instead, we propose looking into laser cutting or suction molding.